Bilasurf, new methods for surface functionalisation

of complex 3D parts using a laser-based high-rate process

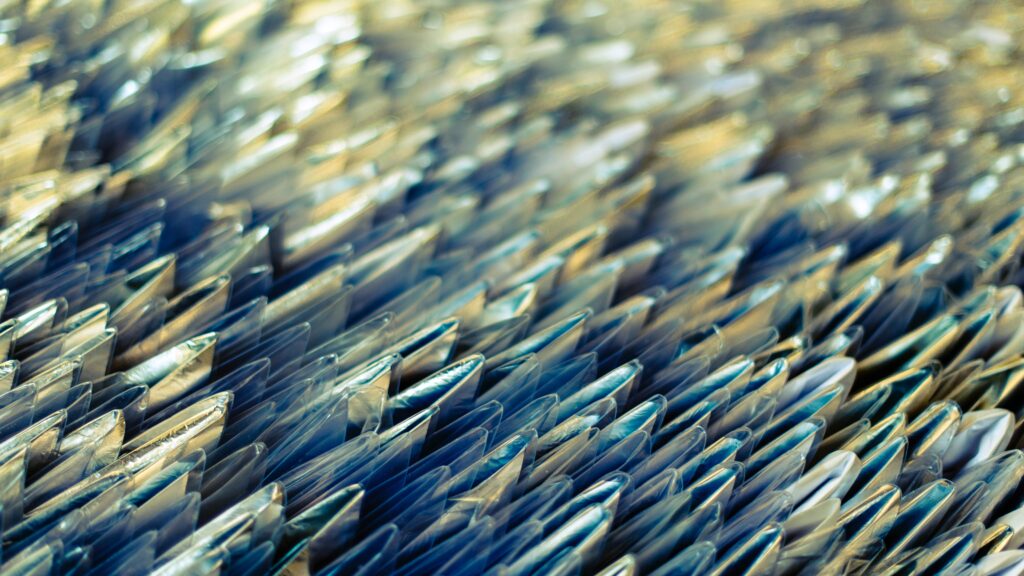

BILASURF is a new European initiative to develop a solution for surface functionalisation, which aims to reduce friction and improve the environmental footprint of industrial parts.

Technology

Design

design procedure for the surface geometry

Laser

laser technology able to process large, complex shaped 3D parts.

Inline monitoring

monitoring system for acoustic emission and vision-based geometrical inspection.

Integrated system

3-modules machine for: handling large and complex 3D parts, inline monitoring, and laser and optics .

Guide

guidelines for the manufacturing of rotating 3d parts which are not covered by the existing standard

Applications

Energy

Enhance the turbine efficiency and broaden the operation range resulting in higher revenues due to a better technical and overall product.

HVAC

The technology offered by BILASURF can reduce friction in order to improve fans performance, achieve higher efficiency and reduce energy use.

Other

Development of an integrated high-speed surface functionalisation system based on laser technologies will enable functionalisation processes.

Our blog

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Stay tuned

Subscribe to our newsletter and be the first to be updated on our latest developments.

The most economical solution that helps you secure your family's future

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

What our insureds say

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.